Reliable Printing: The Key to Safe and Appealing Food Packaging

In the competitive world of food products, presentation is everything. But beyond aesthetics, reliable printing on food packaging plays a critical role in ensuring consumer safety and product quality. Crystal clear information like ingredients, expiration dates, and manufacturing details are crucial for informing customers and preventing potential health risks. Here at Lead Tech-NA, we understand the importance of reliable printing and are here to help you achieve it.

Food Safety First: The Importance of Inks and Regulations

The foundation of reliable printing lies in using food-safe inks. These inks are formulated with ingredients approved by regulatory bodies like the FDA and are designed to act as a barrier, preventing any interaction with the food itself. At Lead Tech-NA, we can connect you with the best food-safe ink solutions for your specific packaging needs.

Printing Processes: Choosing the Right Technology for Durability

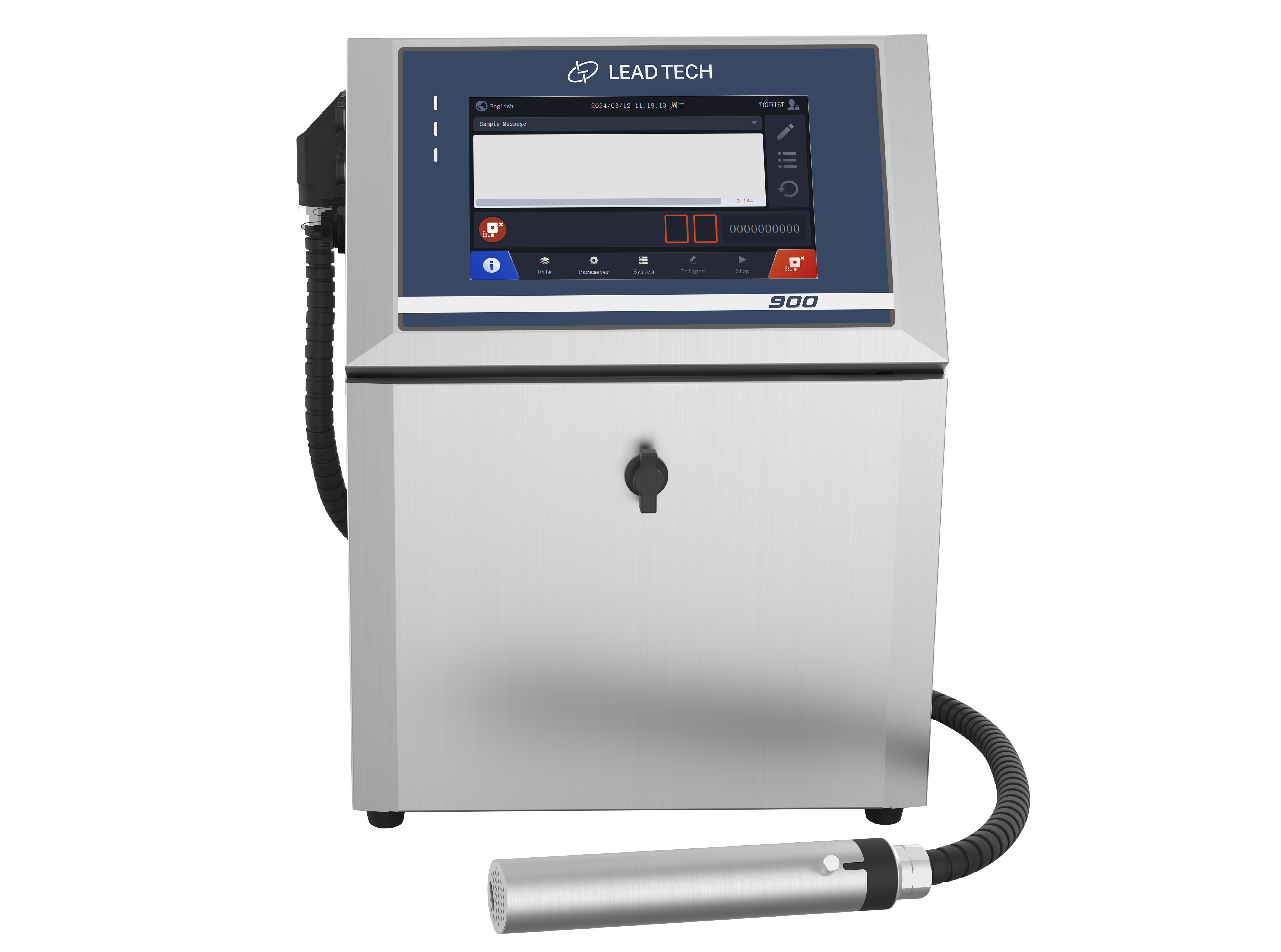

Different printing processes offer varying levels of reliability. Here at Lead Tech-NA, we recommend thermal transfer printing for its exceptional performance in the food packaging industry. This method uses heat to transfer ink from a ribbon onto the packaging material, resulting in high-quality images that resist fading, scratching, and other forms of wear and tear.

Packaging Material Matters: Compatibility for Optimal Results

The type of packaging material you choose can also impact printing reliability. Paper and some plastics are more porous, meaning they can absorb ink, leading to smudging and decreased durability. Our team at Lead Tech-NA can help you find the perfect combination of ink, printing process, and packaging material to ensure long-lasting, vibrant prints.

Beyond the Basics: Tips for Consistent, Reliable Printing

Here are some additional insights from the Tech-NA experts to help you achieve consistently reliable food packaging printing:

- Invest in food-safe coatings: These coatings offer an extra layer of protection against environmental factors that can damage prints.

- Maintain your printing equipment: Regular maintenance ensures your printers function optimally and produce high-quality results.

- Train your staff: Proper printing procedures can significantly impact the consistency and quality of your prints.

- Quality control is key: Regular checks help identify and rectify any printing issues before they affect your product.

By following these guidelines and partnering with Lead Tech-NA, you can ensure your food packaging printing is reliable, meets all safety standards, and showcases your products in the best light. Contact us today and let our team help you navigate the world of food packaging printing solutions!